Greenpath Energy Ltd.

January 30, 2017

Executive Summary

Throughout North America, federal and provincial or state level governments are developing methane emissions regulatory frameworks to be implemented in the coming years with a target of achieving a 40 to 45% reduction in methane emissions from the upstream oil and gas industry by 2025. Alberta has committed to a 45% reduction by 2025, with enhanced leak detection and repair likely to be one of the first policy frameworks which will be used to help achieve this objective.

The three most critical components to a Leak Detection and Repair (LDAR) program are facility inspection frequency, measurement standards, and repair requirements. To date, there is a significant gap in evaluating the current fugitive emissions management practices of the upstream oil and gas industry. The 2014 CAPP Update of Fugitive Equipment Leak Factors by Clearstone Engineering (2014 Clearstone Study) was designed to update leak factors for the National Inventory Report on Greenhouse Gases,1 was based on a significantly smaller data set (approximately 120 facilities) and did not examine the effect of multiple inspections in different years on leaks at facilities. This document – the Historical Canadian Fugitive Emissions Management Program Assessment (FEMP Assessment) – is the first step to fill this gap.

The FEMP Assessment attempts to evaluate current industry LDAR practices, measurement methodologies, reporting mechanisms, leak and vent categorizations, and repair rates from a significant sample of Canadian oil and gas producers. It is the first study of its kind to closely evaluate the performance of these programs and methodically analyze the data to determine the primary sources and associated volumes of leaks and vents from upstream operations. This evaluation primarily serves to more accurately define fugitive emission management practice in Canada, and as the foundation for policy-makers to systematically evaluate regulatory options with regards to LDAR practices. The key output from this study is a large dataset on Canadian LDAR which can be expanded and further analysed at limited incremental cost and made available to stakeholders. GreenPath obtained fugitive emission management data from 14 different companies, accounting for more than 1,000 facilities, representing more than 1,200 different facility inspections, which detected over 10,000 leaks.

The data showed that, in general, existing FEMP programs have been targeting facilities with the highest leak rates. However, the sample size on small facilities (well-sites, batteries without compression, etc.) is too small to draw definitive conclusions on the leak rates by facility.

CONCLUSION #1: INCONSISTENT HISTORICAL LDAR DATA

The most important finding of the study is the need for industry to capture consistent, credible data: good data drives good decisions. As the industry moves forward to address the challenge of reducing methane emissions, the capture of concise, consistent, credible data will be critical to develop regulations which minimize cost to industry while maximizing methane reductions. To that end, GreenPath Energy has developed a standardized data capture template best practice recommendation which should be considered in go-forward FEMP programs. This template is attached in Appendix E. This data capture template has also been vetted by several LDAR subject experts, and has been deemed to contain the information required to produce credible, and consistent data sets, which will assist industry in drawing valuable conclusions from future data collected.

A key gap in the report is the lack of leak repair data. This study captures a wide array of data on leaks at upstream oil and gas facilities, but does not comment on repair effectiveness. The study also identifies the opportunity for improved consistency in measurement and reporting mechanisms for fugitive emissions. An investment in these opportunity areas will build a complete profile of fugitive emissions management practices that will improve industry performance and will ultimately support government’s objective of achieving significant methane emissions reductions in the upstream oil and gas industry in Canada.

CONCLUSION #2: DATA ANALYSIS SHOWS VALUABLE TRENDS

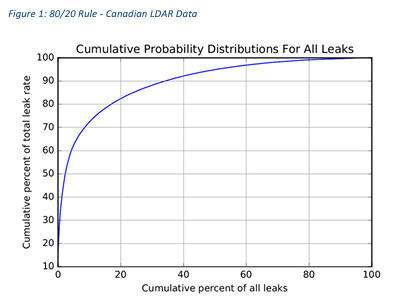

As depicted in the figure above, it appears that the 80/20 rule applies to Canadian LDAR data. Approximately 80% of the total leak volume comes from approximately 20% the total leak count. This information supports the notion that a multi-layered cost-effective LDAR program methodology may be viable as it would allow for high level screening of large emission sources followed up by focused on-site assessments/repair. Technologies are rapidly developing to cost effectively identify major emission sources, and when paired with existing LDAR practice may serve to increase overall cost-effectiveness of LDAR programs.

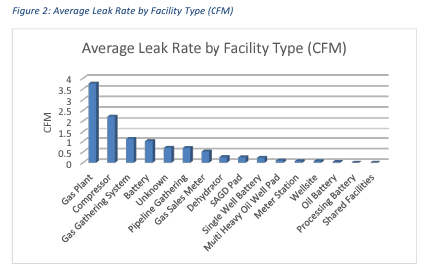

Within the data set, we can also see that historical Canadian LDAR programs which focus on large complex facility types (Gas Plants, Gas Gathering Systems including Compressor Stations, and Oil Batteries) appear to be effectively targeting the highest probable leak rate facilities. This can be shown in Figure 2 below. Another important conclusion that can be drawn from the current data set is that smaller/less complex facility types (wellsites) are less leak prone. The one limitation on this conclusion is the small sample size related to wellsites and smaller facilities.

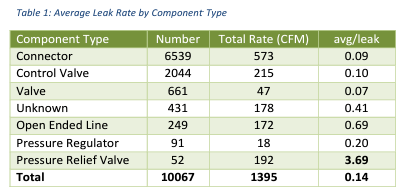

As shown in Table 1 above, the most common leaking components are connectors and control valves, but on average these leak point sources are small in volume. On the other hand, pressure relief valves are seldom found leaking, but when they do leak, could result in significant leak volumes. Appendix B provides more detail on the frequency distribution of leak volumes by component type.

NEXT STEPS

Tools and methods have been built to analyse large volumes of data quickly and consistently. As additional historical and future LDAR data becomes available, more detailed analysis can be undertaken.

# 16-ARPC-02