SILIXA

December 12, 2017

Executive Summary

Distributed fiber optic sensing offers several benefits over conventional technologies for well integrity and production monitoring. Continuous acquisition from all points along the instrumented well path means that events and features can be captured without the need to place point sensors at the right depth at a specific time. This allows the whole well to be logged simultaneously, allowing for events to be verified over an extended period of time (repeatability). It also permits the stacking of data to enhance the response of continuous phenomena. Finally, it allows for the detection of intermittent phenomena that may be missed during time-sensitive methods of acquisition (e.g. wireline).

Given its nature as a measurement along the entire wellbore and its track record for production monitoring, the same principle can be applied to leak monitoring behind casing. With the expected 20dB increase in sensitivity in the new Carina™ Sensing System, the DAS technology should be a suitable candidate for detecting gas behind casing in abandoned wells.

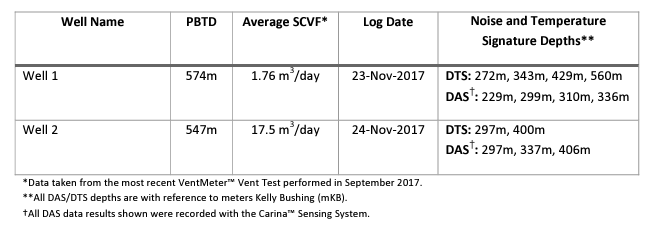

To this end, two wells were logged during this campaign for client. In general, the results from the two wells were good with both temperature and acoustic responses pointing to potential leaks and/or gas movement at the depths listed in the table below. For detailed results, please consult Section 6.

# 16-WARI-03