Valeria Di Filippo, Ashraf El-Messidi, Ammar Abdilghanie Mohammed (PhD), Pejman Kazempoor (PhD), Jianmin (Jimmy) Zhang (PhD), Nasr Alkadi (PI, PhD)

Baker Hughes, GE

May 23, 2019

Executive Summary

This report presents the pioneering work performed by the BHGE team for the Environment and Climate Change Canada (ECCC) to develop a continuous measurement-and-model based component-level emission monitoring solution using BHGE methane sensing and analytics platform LUMENTM for selected oil and gas sites. The main objectives of the research program are as follows:

The BHGE approach for the time-bound, real-time operation related Emission Factor determination is a departure from the industry status-quo over the past decades. Utilizing the power of the digital age technologies, i.e., edge/cloud computing, state of the arts methane continuous monitoring/sensing as well as big data analytics, the LUMENTM platform solution produces preliminary unbiased emission factors which reflect, among other, different equipment operating modes, maintenance conditions, age, location and site production levels. The method considers all-encompassing sets of field conditions in estimating statistical mean emission levels for a given equipment component. This robust technique is envisioned to bridge the existing gap in understanding real equipment operational performance as it relates to frequency and intensity of methane leaks over time.

It should be noted that the emission factors developed in this study represent a limited sample size and may be insufficient for a statistically significant emission factor trend. However, the method is well applicable to broader and extended deployment to produce statistically significant emissions factors for defined sets of equipment components.

This project started in August 2017 when the BHGE research labs worked on development of the LUMEN sensor technology used in this field studies. It was funded jointly by the ECCC and Petroleum Technology Alliance Canada (PTAC) with in-kind support from the Bonavista Energy Corporation which coordinated with the BHGE team all project activities including the site selection as well as purview of daily activities during field preparation, deployment, and post deployment measurements and data analytics campaigns.

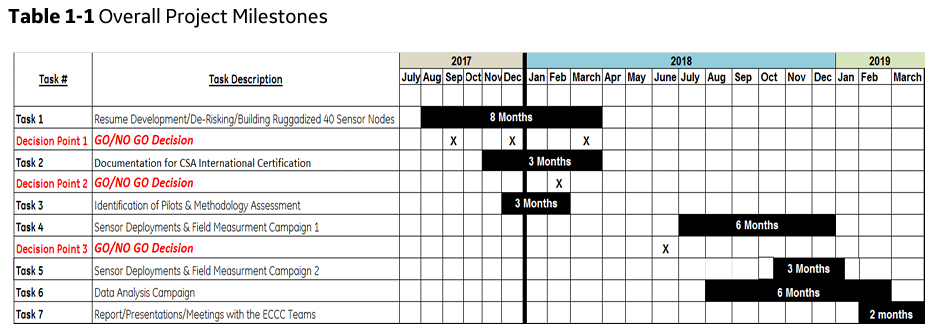

The Table 1.1 shows the overall project milestones from inception to completion. Equipment component leaks and vents that are subject to EPA/EC emission factor reviews were identified during boots on the ground visit on April 2018. Among the seven selected Bonavista production sites, a total of 78 components were screened using portable methane detector. Out of the 78 components screened the team qualified 54 as the representative components for this study. From July to November 2018, the project team deployed a total of 56 LUMEN methane sensors in the seven Bonavista sites, all located in Rimbey, Alberta, Canada. The sensors continuously sampled 54 component level methane emissions over a total period of 8 months for the first 3 sites and 4 months for the rest (the site numbering details in the Figure 1-1).

Sampling frequency was determined at two hertz (or one sampling every 2 seconds). This fast sampling pace by the BHGE patented technology enabled the LUMEN sensor network to capture the dynamics of emissions data resulting from various operating conditions and site events on a continuous basis. The sensor data were constantly transmitted via cloud to EIC servers for further modeling and analysis.

The collection of sensor node data (191 million data points) were carefully processed and thoroughly filtered before going through a series of format transformation and eventually being fed into the “Near-Field Plume Dispersion Model” where the measured methane concentration (ppm) data were converted to leak rate (scfm).

After obtaining a full timeseries of concentration and corresponding leak rates for each node, bootstrap resampling was performed to quantify the random errors and provide a confidence range for the statistics reported. The mean leak rate for each node was calculated and compared with the like-component as well as other types of components in the same facility. Working closely with the operator Bonavista, the team was able to link several key reported events to the revealing timeseries trending, which corroborated the LUMEN data and validated the assumptions that operators could use the sensor platform as an asset management tool to assess equipment conditions for maintenance scheduling purposes.

Although Hi-Flow Sampler measurements may provide true emission behavior of a component during testing time, operators relying on such short-duration checking may grossly over-generalize their component emission characteristics.

Towards the end of LUMEN work flow, time-bound and component-specific emission factors were calculated and compared with the EPA/EC corresponding Emission Factor values which are the industry-wise average.

Key Findings and Results

Key learning discussions

Emission Factor Comparisons

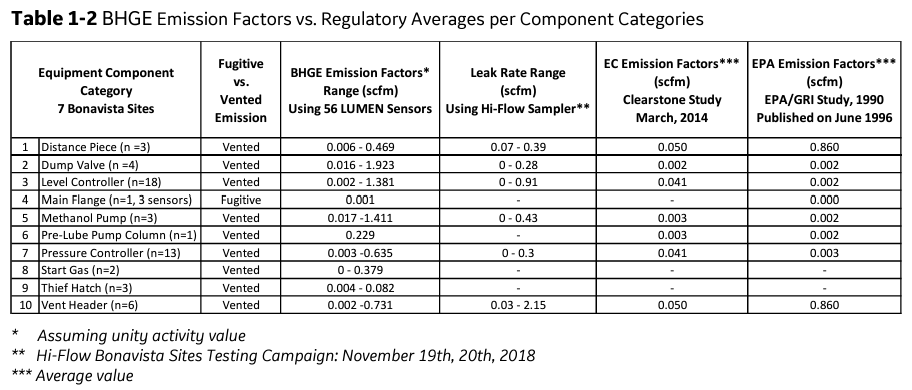

The BHGE emission factors were compared with the data from the 1996 GRI and EPA study and 2014 Canadian-EC Clearstone study as shown in the Table 1-2. The regulatory agencies adopted methodologies (see more details in the Section 6) in emission data collections including one-time measurement, and/or an average of reported emissions, and/or an approximation based on models and correlations. The BHGE approach was based on continuous measurements methodology.

The ranges of BHGE emission factor statistical means for each component category were calculated and listed in the Table 1-2. We found that the continuous measurement approach over an extended period generated numerous insightful understandings on leak source characteristics and signatures over a wide range of operating and environmental conditions. The time-bound, site-specific emission factors add an important dimension to current the EPA and EC emission regulatory methodologies.

Due to limited sample size (54 components) the BHGE emission factors developed in this study may not be very good representations to the entire component population. However, it sheds light on the needs of developing continuous-measurement-based emission factors that are appropriately scaled to target super emitters, i.e., the top 5% of leaks at compression facilities which contribute to 68% of the total emissions. This illustrates the importance of adequately characterizing “super-emitters” while counting emission inventories and trying to apply the emission factors obtained in the studies to various regions or for whole industry-wide estimates.

Site to Site Emission Rates Variability

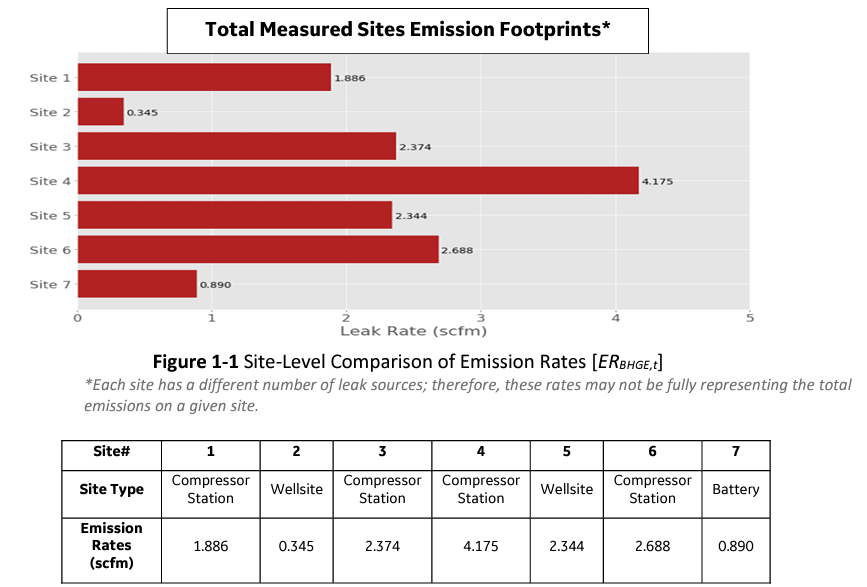

Figure 1-1 shows the emission footprints of the seven Bonavista sites that can be categorized into three types, i.e., compressor stations (4 sites), wellsites (2 sites), and a battery site. Understandably the site functionality correlates their total emissions. In most of the cases, compressor station sites emit more gas than the wellsites due to the distance piece vent emission together with other sources as indicated by individual “grouping” of emission rates. It should be noted that the sample size of leaking components may be insufficient for identifying statistically significant trends among sites.

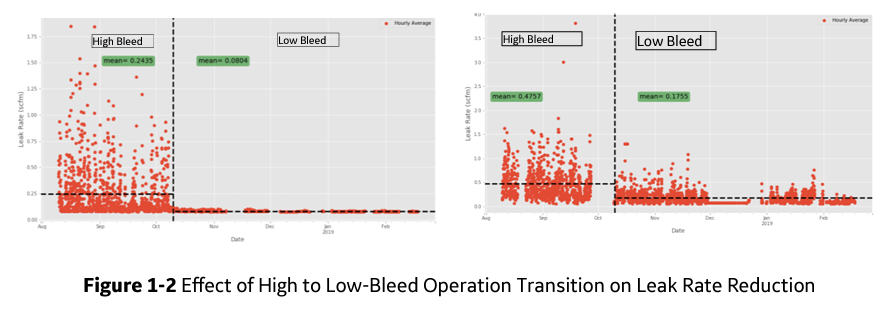

Emission Reduction Quantification due to Transition from Hi-Bleed to Low-Bleed

The emission reductions resulted from replacement of Hi-Bleed controllers to the Low-Bleed were captured and quantified by the LUMEN monitoring system as shown in the Figure 1-2. During the testing period, Bonavista replaced 5 high-bleed controllers with the low-bleed models on two separate occasions. At the sites 1 and 2, the maintenance event occurred on October 10, 2018. The controllers (all categorized as separator pressure controllers) were monitored by the LUMEN sensor nodes 10, 23, 25 and 92. The second event occurred on November 30, 2018 at site 6 where the controller was monitored by LUMEN sensor Node 63. As expected, the controller upgrade at the site dramatically affected the emission behavior. The LUMEN sensors clearly recorded the two distinct emission levels before and after the equipment upgrade (delineated by the vertical dash line plotted on the date of controller replacement). The mean of realtime leak rate from the high-bleed controllers were about 2 to 3 times higher than that from the low bleed controllers, a very responsive emission trending to show the emission reduction.

Correlation of Operational Parameters and Emission Rates

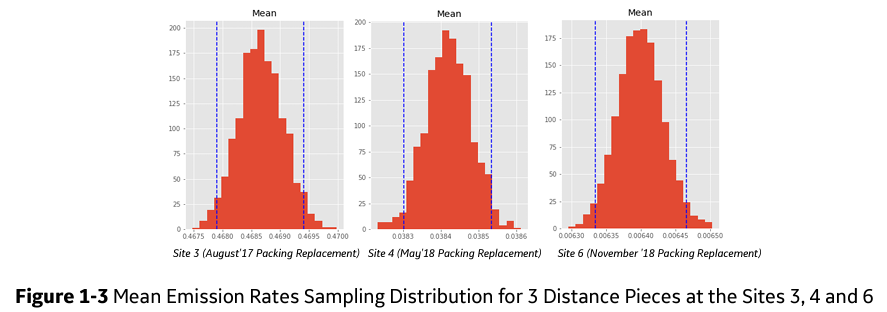

A strong correlation was observed between emission rates at compressor rod packing vents (distance piece) with increased site inlet pressure. Other operational parameters such as replacement of rod packing were strongly correlated with lower emissions rates. There were also evidences of a correlation between higher emissions and compressor age. By comparing the LUMEN measurements to the sites service records, we notice that newer packing lead to emission reductions based on the distance pieces data. Bonavista service records indicate that Site 4 (LUMEN Sensor Node 46) had new packing installed recently in May 2018. Site 6 (LUMEN Sensor Node 69) had the 1st stage repacking completed recently in November 2018, while the last service for Site 3 (LUMEN Sensor Node 31) compressor packing was completed back in August 2017. Referencing Figure 1-3, it is evident that distance piece emission rates from sites 4 and 6 were one order lower than that of site 3.

Distinct Emission Footprint Level Controller Operations – Separator vs. Compressor

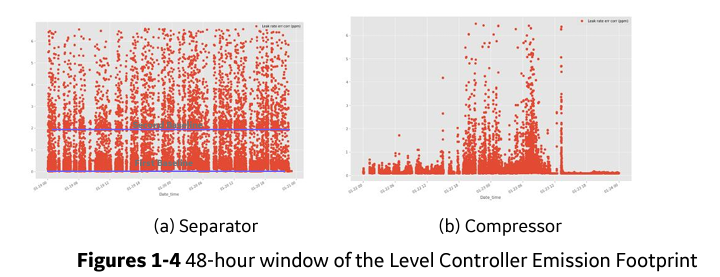

Figure 1-4 shows two distinct emission footprints for level controllers attached to a compressor and a separator, respectively. The emission signature of the separator level controllers had an intermittent behavior that was attributed to snap action (on/off) mode. The release of gas was intermittent and short lived, the dynamic component of the reading, this is the second “baseline” that can be observed in the figure, leveling at around 2 scfm. The bottom baseline belongs to the static component of the reading. The frequency of the gas release is dependent on the frequency the liquid needs to be dumped to lower the level of the liquid.

In stark contrast the compressor level controllers showed more continuous, unimodal emissions, mostly in low levels with occasional spikes, a behavior attributed to the throttle action mode of the level controller.

Finally, with the official LUMEN product launch, BHGE is positioned to scale up this type of research programs that could help customers to understand their emissions footprint as well as the regulatory agencies to develop new measured-based emission factors for the whole industry sector. By design, this study was limited to seven sites and ten different types of components categories (Distance Piece, Dump Valve, Level Controller, Main flange, Methanol Pump, Pre-Lube Pump Column, Pressure Controller, Start Gas, Thief Hatch, and Vent Header). The BHGE team is ready to expand scale of the field monitoring services such that more diversified sites and equipment components are covered to enable ECCC to promulgate a high-fidelity emission factor database based on factual measurements considering of parameters such as the age of equipment, rated capacities, materials, volumetric throughputs, geographic regions, operation modes, and potentially other factors.

Main Body of Report – BHGE Methane Emission Factors

Technical Appendices – BHGE Methane Emission Factors

Full Report – BHGE Methane Emission Factors

# 17-ARPC-11